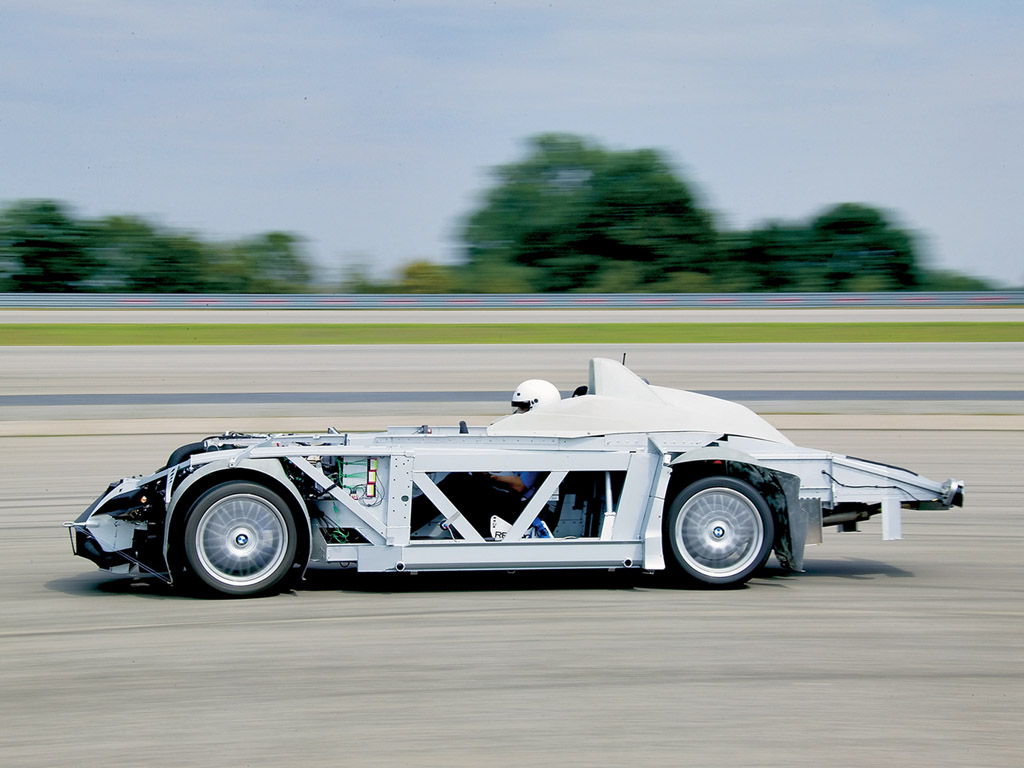

2004 BMW HR2

|

Price |

-- |

Production |

-- | ||

|

Engine |

6 liter hydrogen V12 |

Weight |

3440 lbs | ||

|

Aspiration |

-- |

Torque |

-- | ||

|

HP |

285 hp |

HP/Weight |

12 lbs per hp | ||

|

HP/Liter |

47.5 hp per liter |

1/4 mile |

14.9 @ 97 mph | ||

|

0-62 mph |

approximately 6 seconds |

Top Speed |

185.5 mph |

(from BMW Press

Release) Hydrogen does not only mean top performance in

rockets traveling to outer space: BMW has proven what the hydrogen

car is capable of, setting 9 records for cars powered by a

hydrogen-fuelled internal combustion engine. "Nine records marking

the start into the hydrogen age. BMW technology has already come a

long way. Now, together with politicians and the energy industry, we

must turn our vision of sustained mobility into reality", stated

Professor Burkhard Göschel, Board Member of the BMW Group, during

the speed record trials in Miramas. Achieving this amazing success

at the high-speed Miramas Proving Grounds in France, the BMW Group

has clearly proven its conviction that hydrogen is able to replace

conventional fuel without requiring the driver to compromise dynamic

performance.

The specifications of the H2R Record Car are a testament to this

possibility. The 6-liter V12 engine develops an output of more than

210 kW or 285 bhp. This engine propels the BMW prototype to 100 km/h

in approximately 6 seconds and gives it a top speed of more than

302.4 km/h (185.5 mph). Based on the gasoline power unit featured in

the BMW 760i, BMW's hydrogen combustion engine boasts the most

advanced technologies such as BMW's fully variable VALVETRONIC valve

drive.

The main modifications to the engine involve the fuel injection

system adapted by BMW to the special attributes and requirements of

hydrogen. The H2R Record Car benefits from the results gained in

series development of BMW's future hydrogen engine for the world's

first premium sedan built for dual-mode operation.

BMW will launch a dual-mode version of the current 7 Series during

the production cycle of the present model, thus introducing the

first car of its kind able to run on both hydrogen and gasoline.

The H2R prototype set the following records shown here in terms of

times measured and speed achieved:

BMW works drivers Alfred

Hilger, Jörg Weidinger and Günther Weber took turns at the wheel of

the Record Car during their record-breaking session.

BMW's motive in setting up these records was not only to prove the

power and performance of the hydrogen engine. In addition, the

reliability and durability of the technology used clearly

demonstrates BMW?s leadership in developing the hydrogen engine to

production standard. In this process BMW is concentrating on the

combustion engine, simply because the combustion power unit, given

the sum total of all its features and characteristics, still offers

the largest number of advantages and benefits all in one.

The H2R Record Car: developed in just 10 months

The BMW H2R Record Car

was conceived, designed and developed by BMW Forschung und Technik

GmbH, the legendary subsidiary of BMW AG. The expressive, purposeful

exterior design was created by DesignworksUSA, the California-based

strategic design consultancy owned by BMW Group. The name ?H2R?

stands for ?Hydrogen Record Car?.

"We had just 10 months to develop the H2R prototype", states Jürgen

Kübler, the H2R Project Manager. But a short time span like this is

quite normal for the creative engineers that make this Company so

very special.

In the process the engineers and development specialists were of

course supported by three factors: First, the components featured in

BMW's hydrogen production car of the future have now reached a high

degree of maturity allowing their straightforward adaptation for the

record car. Second, the development specialists were able, in the

development process, to use proven BMW chassis and suspension

systems which matched the strict requirements. And third,

far-reaching use of CAD technology allowed for an effective and

efficient development process.

The engine: series production 12 cylinder specially adapted for hydrogen

The "heart" of the H2R

Record Car is based by and large on BMW's top-of-the-line power

unit, the Company's 6.0-liter V12. It is able to run on hydrogen

fuel through the adjustment of engine management as well as the

fuel/air mixture formation components.

The most significant differences in terms of the engine's structural

components are the hydrogen injection valve and the choice of

materials for the combustion chambers: Contrary to the production

engine with fuel injected directly into the combustion chambers

themselves, the injection valves in the hydrogen engine are

integrated into the intake manifolds. And for the specific speed

record requirements to be fulfilled in this case the hydrogen

combustion engine was designed and built for single-mode operation,

running exclusively on hydrogen.

This allowed the engineers to set up and tune the engine

specifically for hydrogen requirements, for example by using special

valve seat rings made of an appropriate material. The reason for

this necessity is that hydrogen does not have the lubricating effect

of a conventional gasoline/air mixture. It is worth noting in this

context that this need to cope with a lower level of lubrication has

come up before. With the introduction of unleaded gasoline,

production engines have been built with even stronger and more

resistant materials.

Hydrogen providing enhanced efficiency

The combustion

properties of hydrogen are quite different from those of gasoline or

diesel: While hydrogen burns faster than conventional fuels under

normal air pressure, the combustion temperature is slightly lower

than in the case of gasoline.

Inside the engine the high combustion speed of the hydrogen/air

mixture generates a higher temperature than in an engine running on

gasoline. Engine management of the BMW H2R Record Car has been

modified accordingly. The hydrogen/air mixture is not ignited until

the piston reaches top dead center, thus ensuring maximum output.

With a gasoline/air mixture burning relatively slowly, by

comparison, the mixture must be ignited at an increasingly early

point as a function of engine speed, the pressure peak thus being

reached just as the piston starts to move down.

A significant advantage of the higher combustion pressure of the

hydrogen/air mixture is that the generation of more power from the

same amount of energy means a higher degree of efficiency.

As desirable as the high standard of ignitability of hydrogen within

the engine may be, it also requires a great deal of attention

outside of the combustion chamber. To avoid misfiring, for example,

BMW's engineers have developed a specific gas cycle and injection

strategy, with BMW's VANOS infinite camshaft adjustment

masterminding the share of residual gas according to specific,

on-demand requirements:

Before the hydrogen/air mixture is able to flow into the cylinders,

the combustion chambers are cooled by air to ensure that the

fuel/air mixture is not able to ignite in an undesired, uncontrolled

process.

VALVETRONIC providing optimum conditions for hydrogen drive

Exclusive to BMW,

VALVETRONIC technology serving as a standard feature to mastermind

the valves on the 12 cylinder gives the Company's engine development

specialists an ideal tool for controlling this demanding gas charge

cycle. VALVETRONIC controls not only the duration of valve movement,

but also the actual valve lift. This effect is provided by an

intermediate lever between the camshaft and the two intake valves on

each cylinder infinitely modified in its position relative to the

camshaft by an additional eccentric shaft operated by an electric

motor. Depending on the position of this eccentric shaft, the lever

transforms the "hump" on the cams into a larger or smaller valve

movement.

VALVETRONIC is based on BMW's infinite camshaft adjustment process.

Already well-known under its trade name VANOS, this system is an

integral part of the VALVETRONIC concept. Incorporating a

hydraulically controlled adjuster unit in the camshaft drive, VANOS

modifies the beginning and end of the valve opening period, fully

variable valve management serving to adjust the gas charge cycle in

the 12 cylinder power unit perfectly to the requirements and

characteristics of hydrogen drive.

Special injection valves for hydrogen power

With hydrogen being

injected into the intake manifold as late as possible, the injection

valves have to meet very demanding requirements. Hence, the valves

are a trendsetting new development for BMW. And since gaseous

hydrogen takes up a larger volume per unit of energy than liquid

gasoline, the hydrogen injection valves are larger than conventional

injection valve units.

In addition, the valves have to cover a far wider range of different

requirements, operating under all kinds of system pressure levels

and with injection periods ranging from very short to relatively

long. One of the main objectives in developing the valves was to

inject exactly the right amount of hydrogen required into the intake

manifold within a very short time-frame at very high engine speeds

and under full load.

A clean mixture formation process:

less fuel consumption under part load, extra power under full load

Under full load the 12

cylinder power unit runs on a fuel/air mixture of

lambda = 1. This is exactly the same mixture we find on a

state-of-the-art gasoline engine and one which, in principle, offers

the highest and most efficient power output in a combustion engine.

Under part load - again a significant benefit offered by hydrogen -

the engine runs efficiently in the lean burn mode with surplus air.

Under specific conditions, that is with a specific fuel/air mixture,

the combustion of hydrogen leads to the generation of nitric oxides.

This mixture "slot" starts slightly above lambda = 1 and extends to

the range of lambda > 2.

The simple solution to this problem is to leave out this mixture

"window" altogether, since it is not required for running the

engine. Hence, the fast management system controlling the BMW

hydrogen engine skips this operating range completely, thus avoiding

NOx emissions in the process. As a result, the H2R Record Car?s

emissions are limited, for all practical purposes, to nothing but

steam.

Safety technology

The fuel system featured

in the BMW H2R Record Car is based on a proven series development

concept. Fuel is filled into the tank of the H2R prototype at a

mobile hydrogen filling station through a manual tank coupling. The

vacuum-insulated, double-walled tank has a capacity of more than 11

kilos of liquid hydrogen and is fitted next to the driver's seat. A

total of three valves ensure optimum safety, the operating valve on

the tank opening at a pressure of 4.5 bar.

Two additional safety valves rule out any dangerous consequences of

possible leaks in the jacket around the tank serving to keep the

hydrogen at the low temperature required, opening up as soon as

pressure within the tank exceeds the limit of 5 bar. This

double-redundant safety system guarantees optimum safety at all

times, ensuring that the hydrogen tank will not burst as a result of

excess pressure.

Heat exchanger instead of a gasoline pump

Gas pressure builds up in the fuel supply system simply because of the rising temperature of the cryogenic, liquid hydrogen in the tank and is kept at an operating pressure of approximately 3 bar by a tank pressure controller. Then the coolant running within the 12 cylinder power unit warms up the hydrogen gas in a heat exchanger to ambient temperature.

Valve technology

Additional valves

monitor the pressure of gas in the fuel pipes leading to the engine:

Cold low-temperature valves inside the tank control the removal of

hydrogen from the tank itself. Should any of the pre-flow pipes

develop a leak, with supply pressure dropping below 0.4 bar, the

fuel supply valves close automatically, disconnecting and sealing

the tank off from its surroundings. The supply pipe can also be

interrupted manually by an interruptor tap.

To maintain optimum supply pressure on the injection valves at all

times ? especially as this pressure may vary as a function of

driving conditions ? engine management reduces pressure in the

supply pipe to approximately 1.2 bar by means of a control valve

fitted specifically for this purpose.

This comprehensive safety system featured in the H2R Record Car is

supervised additionally by a telemetric system of the same type as

in Formula 1. Four hydrogen sensors fitted at neuralgic points - for

example in the tank itself and around the tank coupling - recognize

any leakage immediately and inform the driver accordingly.

Chassis and suspension

Focusing on the

structure and chassis of the BMW H2R Record Car, the engineers and

development specialists at BMW Forschung und Technik GmbH used

series components carried over from a sophisticated, thoroughbred

BMW sports car: the monocoque aluminum spaceframe as well as the

entire chassis and suspension system. High-strength aluminum

structure panels using the advantages of aluminum as a particularly

light material resistant to corrosion fill in the open spaces

between the extra-large extrusion-pressed profiles giving the car

its stable "skeleton".

The result for the driver is a very stable driving experience

without the slightest vibration or body "tremble".

The front suspension is based on a double-wishbone spring strut

front axle together with rack-and-pinion steering, aluminum track

control arms, a tiebar, and an anti-roll bar. The front axle

subframe is formed by a welded aluminum structure made up of

extrusion-pressed profile bars and plates holding all front axle

components and bolted to the body at six points. The track control

arm made of forged aluminum comes complete with two ball joints in

the interest of precise wheel guidance and directional stability.

Wheel guidance and stability at the rear is provided by an integral

four-link axle, a multi-arm principle patented by BMW and rounded

off in this case by an anti-roll bar. Optimum road contact and

safety, finally, is ensured by tires measuring 245/40 x 19.

The bodyshell: outer skin made of carbon fiber

The designers have also

given the H2R Record Car a truly unique body: ?We wanted to embrace

the aerodynamic requirements we defined in the wind tunnel with a

form language that was appropriate to the purpose of the car; the

results are a true expression of the car's functional requirements

and objectives to be clean, fast, and uniquely BMW," said Michael

Scully, Senior Designer of DesignworksUSA , who combines his intense

involvement in motorsports with the intellectual and aesthetic

challenges of multidisciplinary design.

Measuring 5.40 meters in length and 2 meters in width, the body of

the car is designed through and through for optimum streamlining.

And to reach record speeds, the frontal area measures just 1.85

square meters and the drag coefficient is a mere 0.21. At the rear a

20-centimeter-long diffuser prevents air swirl behind the car, which

might potentially slow it down.

The side profile and sheer length of the H2R prototype also serve to

ensure stable driving characteristics at very high speeds. Like on a

Formula 1 racing car, the outer skin is made of carbon-fiber

reinforced plastic offering the optimum combination of superior

stiffness and low weight: Overall weight of the H2R with a full tank

and the driver at the wheel is 1560 kg or 3440 lb.