2006 Audi Dynamic Space Frame

(from Audi Press Release)

AUDI - DYNAMIC SPACE FRAME

Audi Design team contributors: Hans Chou, Toby Gillies, Tony Liu,

Sabine

Lapine, Jae Min, Heather Shaw, Mattijs van Tuijl.

DCC Design Strategy and Communications: Nathan Barbour, Sean Conniff,

Ian

Hilton.

Interns: Zac Atwell, Urlich Bauer, Carey Lyn, Richard Overcash.

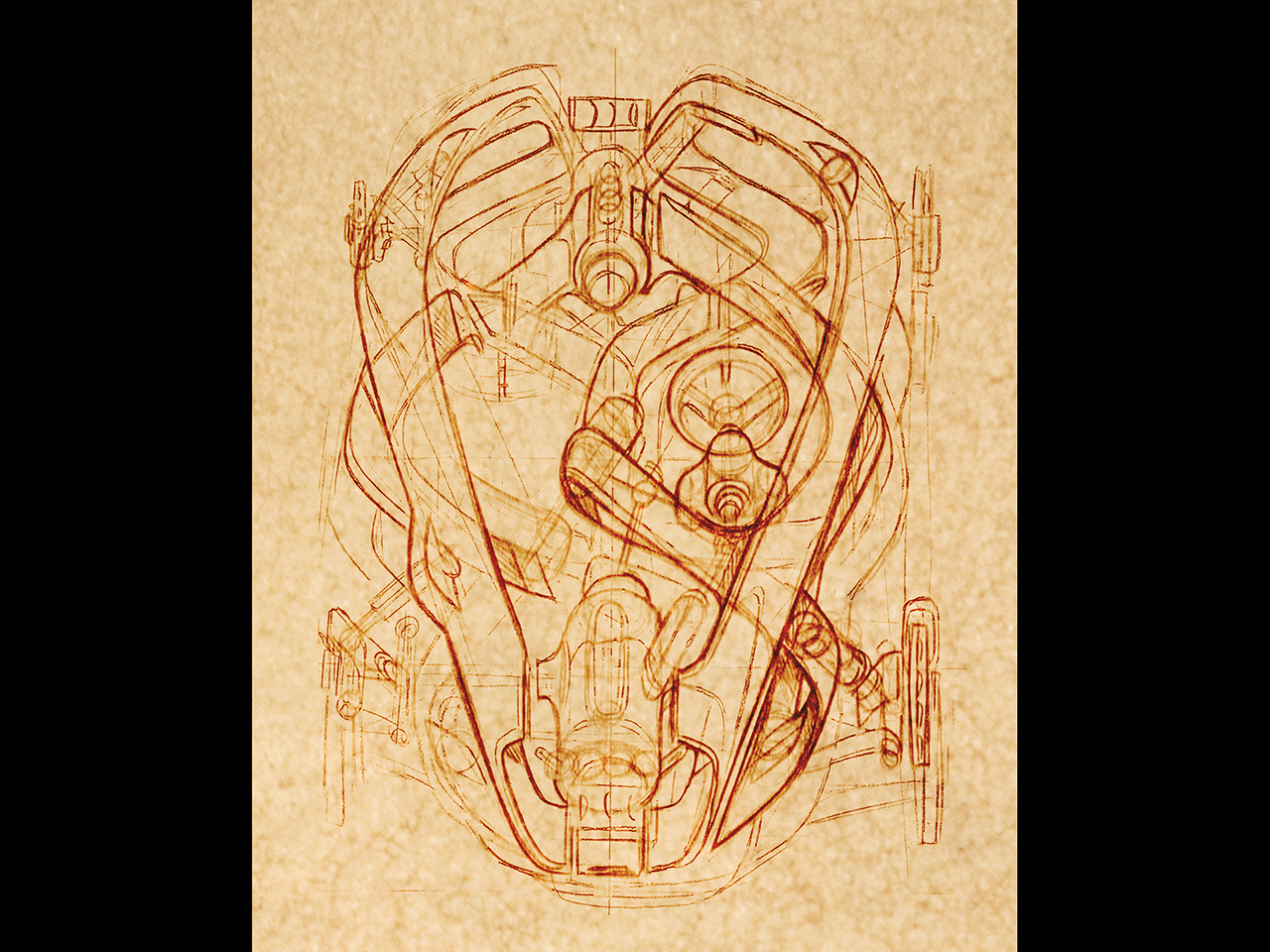

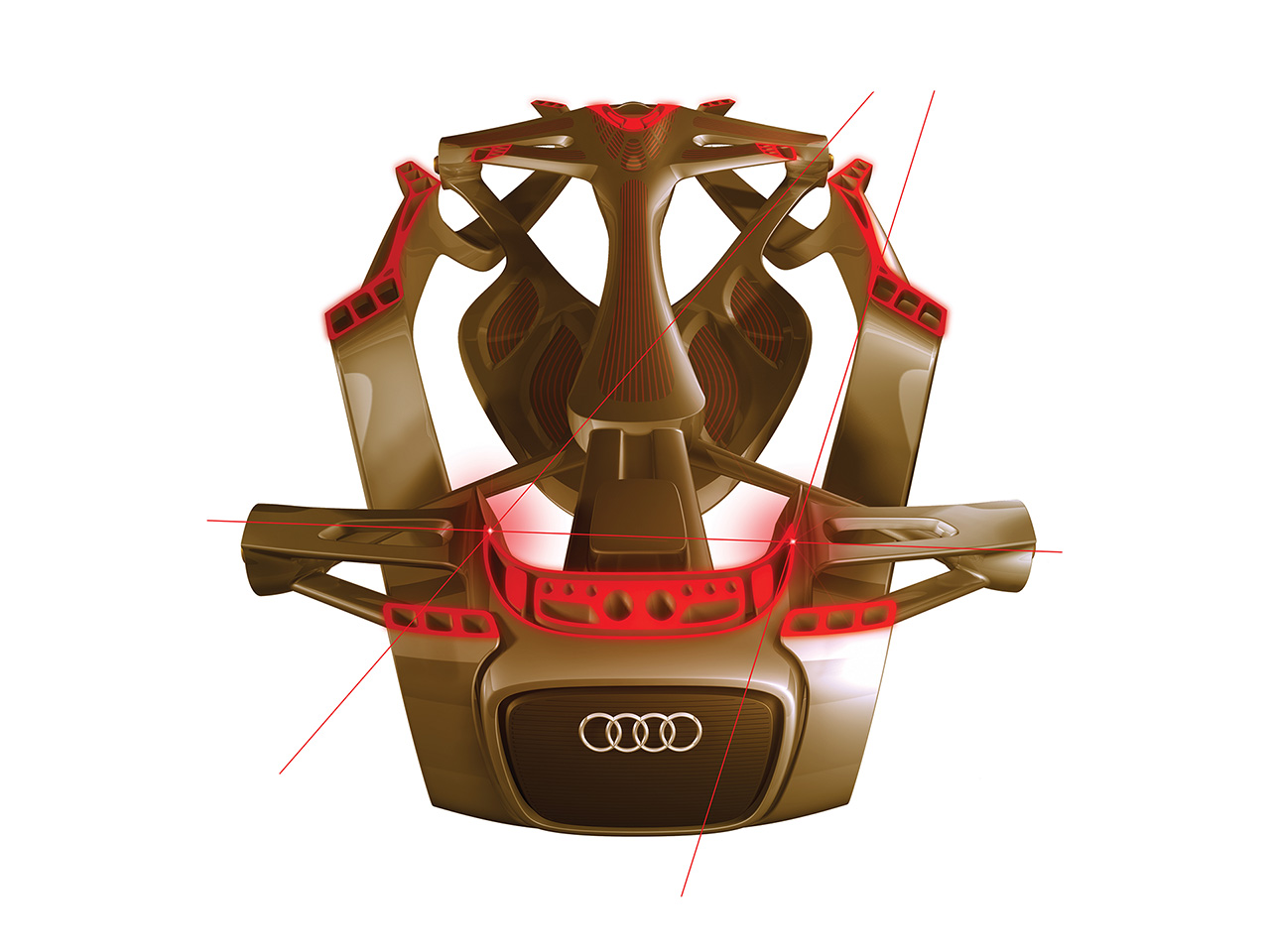

DCC Audi’s answer to the proposed vehicle mandate of 2015 would be

to utilize

a concept similar to the rapid prototyping method of manufacturing

using

advanced materials.

This method of building each vehicle would not only streamline the

manufacturing process by integrating currently separate parts and

processes, it

would also allow an unprecedented level of flexibility and

customization. This

system would theoretically make expensive “tooling” a thing of the

past.

This technique would allow us to realize other benefits such as:

1. Integration of all fluid and electrical channels within the

frame.

2. Suspension and body components comprised of hollow space filled

with fluid

that responds to electrical current, which controls the ride.

3. Utilizing a hydraulic fluid drive in place of a traditional

driveshaft.

4. Simpler recycling & reusability through “all inclusive” single

material dynamic

space frame and in certain cases, interior and exterior.

The Dynamic Space Frame concept would revolutionize the way cars are

designed, produced, and recycled. It would usher in a new era of

automobiles

which would not only address the aforementioned mandate, but take

adaptability

and individuality to new levels.

This concept left us wanting to contribute in some way other than a

conceptual

poster. As a result, we purchased domestic wind power from Renewable

Energy

Choice and had trees planted through Trees for the Future’s Global

Cooling

Program in the hopes of offsetting the resources used for this

project.