2006 Bugatti Veyron W16 Engine

(from Bugatti Press Release) The trials of the fastest road sports car in the world have been successfully completed. One of the most ambitious projects in automobile history is entering its production phase. The first Bugatti Veyron 16.4 cars, built mainly by hand, are already being completed and will be delivered to customers this year.

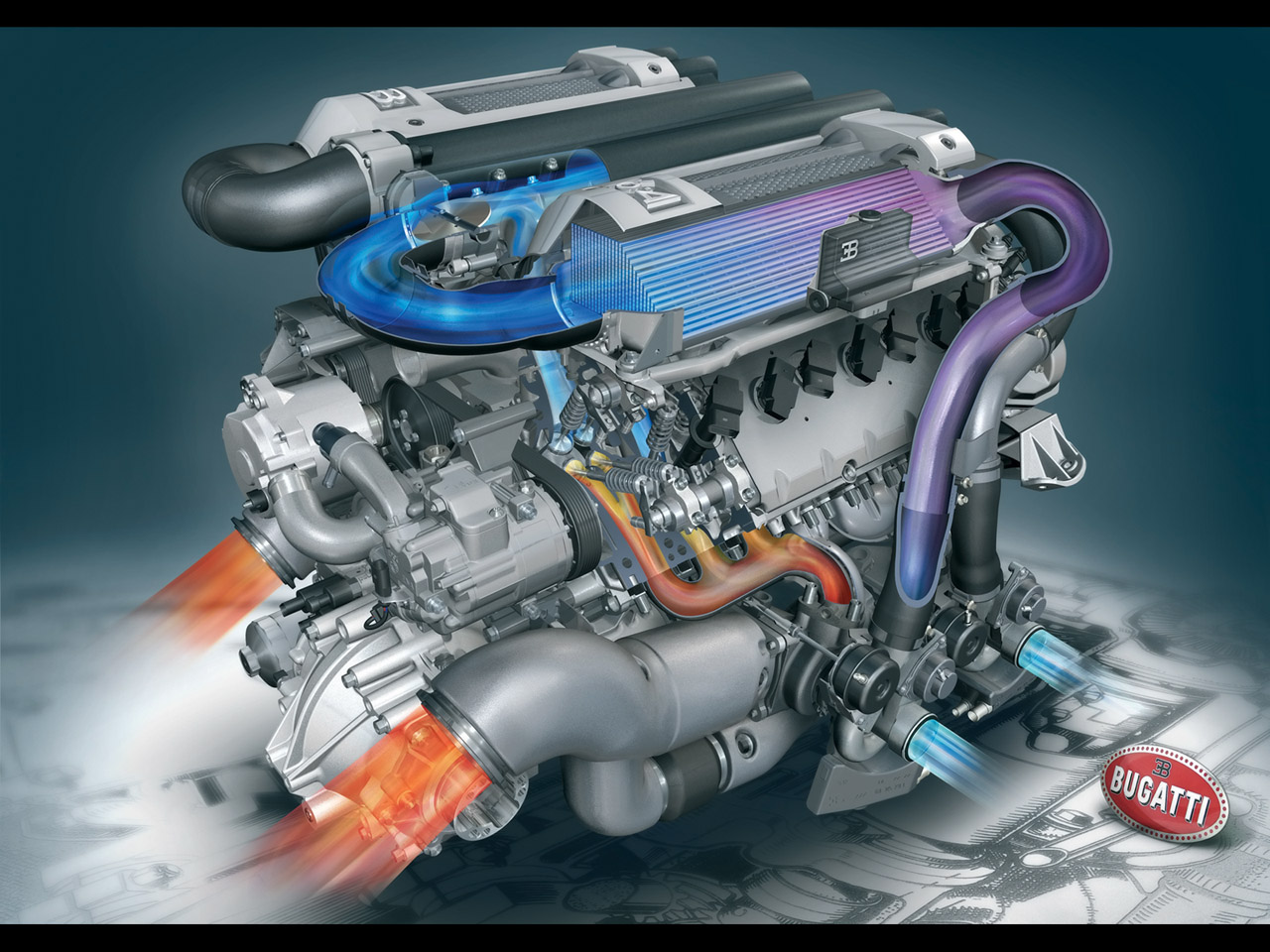

The sports car, capable

of more than 400 km/h, is driven by a 16-cylinder mid-engine, that

at 710 mm

long is no larger than a conventional V12 unit, and due to its

lightweight construction weighs only

about 400 kilos. Its compact dimensions are due to the unique

arrangement of its cylinder banks in

a W configuration. Two VR8 blocks, each with a fifteen degree bank

angle, are joined in the crankcase

to form one engine. Both eight cylinders are set at an angle of

ninety degrees to each other and are

aspirated by a total of four exhaust gas turbochargers. The engine

delivers 1001 HP at 6,000 r.p.m.

and provides a maximum torque of 1250 Newtonmetres at between 2,200

and 5,500 r.p.m.

To apply the power of

the 64-valve unit to achieve satisfactory driving dynamics both in

everyday traffic

and on the racetrack, the Bugatti development team of Dr.

Franz-Joseph Paefgen and Dr. Wolfgang

Schreiber has realized a propulsion unit that is without parallel in

its complexity. If the extreme

engine power is a master stroke of genius, its conversion for road

use is an equally tough challenge.

As Dr. Schreiber says “For 1000 HP propulsion power, the system

demands approximately 2000 HP

to be additionally generated as heat energy during combustion. Half

in each case is dissipated in

the exhaust gas and cooling water”.

To do this, the Bugatti engine has two water circuits. The larger of

the two with 40 liters of cooling

water has three coolers in the front section of the car, to keep the

engine at operating temperature. The second circuit, called the

low-temperature system, has a separate water pump and contains 15

liters of cooling water. These are used to cool, by up to 130

degrees, the charged air, heated during compression in the

turbochargers, in two heat exchangers mounted on the engine. The

cooled, charged air then passes through two “air manifolds” into the

combustion chamber, which it then leaves as exhaust gas at

approximately 1,000 degrees. It then passes through the turbines of

the exhaust gas turbochargers. This causes the exhaust gas to

expand, so that it is cooled by up to about 150 degrees, is then

cleaned in the catalyzer and exhausted.

In addition to its unique compactness, the high performance of the

power unit is the centrepoint of

the development. Lightweight materials are used that not only result

in a low power-to-weight ratio but

also particularly provide the spontaneous response of the moving

engine-internal masses. In addition

to piston rods of titanium, the so called “easy runners”, the

eight-stage oil pump integrated into

the crankcase for dry sump lubrication has light aluminum gears.

Because the arrangement of the

16 cylinders ensures extremely quiet running, only a small flywheel

is needed. The use of motor sport

technology is evident not only from the plasma-coated running faces

of the cylinders but also by the use of high-strength steel for the

shafts and gears in the aluminum crankcase.

Unique in engine design

is the integration of knock and misfiring detection in an ion

current system.

Because the multiplicity of cylinders means very quiet running and

ensures that the velocity difference

will be extremely small in the event of a cylinder misfire,

cylinder-selective detection by measuring

rough running is not reliable enough. Therefore, Bugatti Ion Current

Sensing (BIS) is used. The ion

current flowing at each spark plug at the timepoint of ignition is

monitored by a separate evaluation

sensor system. The data obtained is passed to both engine control

units. If knocking combustion or

a misfire is detected, the associated control unit immediately

initiates countermeasures, such as

retardation of the ignition timepoint, shutdown of the cylinder or

reduction of the charge pressure.

According to the head of Bugatti Unit Development Gregor Gries, “The

aim of our technology is

to generate the maximum performance from the engine in a stable,

clean manner”.

The power generated in

the engine is transferred to the flange-mounted direct manual

gearbox (DSG).

The torque and speed is then transmitted, through the gearing of

seven forward and one reverse gear,

via a universal drive to the front axle gearbox and via a second

universal drive, along the right side of

the engine to the rear axle gearbox. Both the DSG and both axle

gearbox housings are of lightweight

aluminum construction. The drive power is distributed to the front

and rear axles by means of a Haldex

coupling, an actively-controlled multi-disk, inter-axle lock

directly connected to the front axle gearbox.

The following front axle differential distributes the power to both

front wheels. In the rear axle differential

the power is distributed to the rear wheels via a bevel gear and a

further differential. In addition, an

actively-controlled, hydraulically-actuated, multi-disk differential

lock is installed here. When necessary, it prevents speed

differences between the rear wheels and ensures optimum directional

stability when accelerating and when cornering under load. All load

distribution functions are completely automatic and are undetected

by the driver.

The Bugatti marque has

since earliest times been regarded as a central force in the

advancement of

automobile development by innovative solutions. A position

deservedly maintained by the first

high-performance sports car of the modern Bugatti.