2008 Audi R8 TDI Le Mans

|

Price |

-- |

Production |

-- | ||

|

Engine |

6 liter TDI V12 |

Weight |

-- | ||

|

Aspiration |

twin turbochargers |

Torque |

738 lb-ft | ||

|

HP |

500 hp |

HP/Weight |

-- | ||

|

HP/Liter |

83.3 hp per liter |

1/4 mile |

-- | ||

|

0-62 mph |

4.2 seconds |

Top Speed |

205.5 mph |

(from Audi Press

Release) Outstanding Torque for the Top class

Audi is presenting a revolution in the top class the first

12-cylinder diesel engine in a high-performance roadgoing sports

car. The V12 TDI with a displacement of six liters powers a concept

car based on the Audi R8. This unit generates a huge 500 hp and

1,000 Newton-meters (737.56 lb-ft) of torque. Audi is writing a new

chapter in diesel technology with this power unit. Equipped with the

expertise that Audi has built up through its motor sport activities,

the R8 TDI Le Mans in Brilliant Red embodies superb road handling,

pioneering technology and fascinating design.

The V12 TDI is closely related to the engine in the Audi R10, the

two-time Le Mans winner so it catapults the Audi R8 into supercar

terrain concerning performance too. It sprints from zero to 100 km/h

(62.14 mph) in just 4.2 seconds and its top speed is well over 300

km/h (186.41 mph). The peak torque, reached at only 1,750 rpm, paves

the way for effortless acceleration that is unrivaled even at this

level.

The new V12 TDI belongs to Audi's family of V engines but has the

ideal included angle for this engine type of 60 degrees between

cylinder banks. Its highlights include the new chain drive layout

that includes the two newly developed high-pressure pumps for the

common rail injection system.

Its sound is as thrilling as you'd expect in a sports car of this

caliber. For all the subtle smoothness that typifies this design

principle, the twelve-cylinder unit is full-bodied and equipped with

energetic overtones that make no secret of its performance

potential.

The Genes of the Winner

Thanks to their high performance and pulling power, all Audi TDI

engines are ultra-dynamic sources of power. The brand has often

enough demonstrated its sporty character in its production cars,

especially the six- and eight-cylinder 3.0 TDI and 4.2 TDI. Audi has

also been writing a new chapter in its success story on the

racetrack since 2006. The diesel engine in the R10 sports prototype

won its very first endurance race at Sebring, Florida, when it was

pitted against an entire field of gasoline-engined challengers. But

its most crucial victories were surely in 2006 and 2007 in the 24

Hours of Le Mans, when it simply outclassed the international elite.

The V12 TDI race engine in the R10 produces over 650 hp from a

displacement of 5.5 liters, giving it the potential for a top speed

as high as 330 km/h (205.05 mph) depending on the gear ratios. Its

power and sturdiness immediately impressed both fans and experts,

who were impressed by its restrained noise level. Unusual for a race

engine, this powerful Audi diesel makes barely more than a whisper.

Long traditions of motor racing and production technology complement

each other at Audi. The FSI engine of the R10's predecessor, the R8,

captured five wins at Le Mans with a direct gasoline injection

system. Audi is also looking to maximize the advantage by using the

race-tested FSI principle in its production models. The latest

examples of this are the V8 with high-revving concept in the RS 4

and the production version of the Audi R8.

The Drivetrain

The roadgoing version of the new V12 TDI is built at the Gyr plant,

in Hungary. And the R8 TDI Le Mans still has a massive 500 hp on

tap. In developing the six-liter engine, it was a clear priority to

integrate it into the current family of Audi V engines, of which

many thousands of versions with 6, 8 and 10 cylinders have already

been built both gasoline and TDI.

Audi's engineers were in an ideal position to use their experience

building the racing engine to develop the road version. Like the

other power units in this range, the distance between cylinder bore

axes on the V12 TDI is 90 mm (3.54 in.). Yet its included angle is

60 degrees, not 90 degrees. This means no free inertial forces or

mass moments of inertia can occur with the V12. The results are

refined in every respect.

The 83.0 mm (3.27 in.) bore and 91.4 mm (3.60 in.) stroke produce a

total displacement of 5,934 cc just like the 3.0 TDI. At only 684

mm (26.93 in.) long, this large diesel engine is very compact and

just 166 mm (6.54 in.) longer than the V8 TDI. This compact length

is key to accommodating the V12 in the mid-engined Audi R8.

The V12 TDI crankcase is made from gray cast iron with vermicular

graphite a high-tech material referred to as GJV-450 that is

already used on the V6 and V8 TDI engines. GJV-450, made by a

patented casting process, is about 40 percent more rigid and 100

percent more fatigue-resistant than gray cast iron. This enabled the

developers to make its walls thinner, cutting its weight by around

15 percent compared with conventional gray cast iron.

The two cylinder heads are each made from three main elements. These

are a base section made from a high-strength aluminum alloy

incorporating the intake and exhaust ports, an oil-bearing upper

section, and a reinforcing ladder frame supporting the two

camshafts.

The valves are actuated by low-friction roller cam followers; the

compression ratio is 16.0:1. Map-controlled swirl variation of the

combustion air has been adopted from the V6 and V8 TDI engines. This

produces permanently optimized swirl concerning both emissions and

high performance.

Ultramodern Injection Technology

As is the case in the Audi V engines, the no-maintenance chain drive

is mounted at the back of the engine, where it occupies little

space. Its layout has changed on the new V12 TDI. The camshafts'

sprocket engages in an intermediate gear via which two Simplex

chains drive the camshafts. Two more chains drive the oil pump and

the two high-pressure pumps actuate the common rail injection

system.

The two new dual-piston high-pressure pumps form part of the common

rail injection system supplied by specialty manufacturer Bosch. The

two pumps build up a pressure of up to 2,000 bar in the rails. The

piezo injectors with eight-hole nozzles have also been fundamentally

revised.

The high pressure distributes the mixture optimally throughout the

combustion chamber. The result is that the ignition process is

faster, more homogeneous and more acoustically refined. The more

efficient combustion process also increases power output, cuts

consumption and reduces pollutant emissions.

The current generation of so-called inline injectors makes effective

use of the piezo effect: piezo crystals expand in a fraction of a

millisecond when an electrical voltage is applied. The number of

injection processes per operating cycle can be varied across a wide

range thanks to piezo technology reaching as many as five fuel

injection operations in the case of the V12 TDI.

As well as the main injection, pilot and post injections are

possible. Pilot injections tone down the acoustic harshness of the

combustion process. Retarded post injections are designed

specifically to increase the temperature of the exhaust gas,

promoting regeneration of the two standard particulate filters.

The two turbochargers are located on the outside of the engine's V,

each of them supplying one bank of cylinders. Thanks to their

variable turbine geometry, the full flow of exhaust gas always

passes through the turbine, so the chargers respond slickly even

at low engine speeds and operate very efficiently.

The two turbochargers, which generate up to 2.6 bar of boost

pressure, play a crucial role in producing the huge torque of 1,000

Nm (737.56 lb-ft) that the V12 TDI maintains from 1,750 rpm to 3,000

rpm. In developing 368 kW (500 hp), the diesel achieves a specific

output of 62.0 kW (84.3 hp) per liter displacement.

Two large intercoolers reduce the temperature of the compressed air.

The V12 has a twin-pipe exhaust system with two particulate filters.

The intake system is similar in structure with one air cleaner per

cylinder bank, with an airflow meter behind it. Two control units,

sharing the workload in a master/slave principle, manage events in

the engine.

The Audi R8 TDI Le Mans already fulfills the Euro 6 emissions

standard that is likely to take effect in 2014 and calls for sharply

reduced nitrogen oxides. By also designing in ultra-precise fuel

metering by the common rail system, Audi's engineers have made full

use of current clean diesel technology.

The heart of the system is a special catalytic converter downstream

of the oxidizing catalyst and the particulate filter. The second

component in the system is an additional tank containing an aqueous

urea solution. Small quantities of the solution, known as "AdBlue,"

are injected into the exhaust system. The hot exhaust gases break

the solution down to form ammonia that splits the nitric oxides into

nitrogen and water. The system remains effective for the entire

service life of the vehicle.

The dynamic character of a sports car depends not just on its

performance and torque; the transmission ratios have to be right

too. In keeping with the character of a high-performance sports car

with unbeatable torque potential, the transmission in the R8 TDI Le

Mans has six manually operated gears.

The manual transmission is very compact in design. Together with the

small-diameter double-plate clutch, this means it can be installed

low down. The manual transmission has very short shift travel and

utterly precise guiding of the shifter into the open gear lever

gate. It is made from polished aluminum, has an agreeable feel and

exquisite sports car looks.

Such a high-performance Audi also has quattro permanent all-wheel

drive. In the case of this mid-engine sports car, power is

distributed variably between the front and rear wheels from a

starting ratio of 40:60 to optimize the handling.

The Design

The R8 TDI Le Mans with Brilliant Red bodywork looks even wider and

more resolute than the core model. It shows its potential through

its muscular proportions, accentuated wheel arches and even larger

air apertures. The rhombus-pattern cover on the air inlets and

outlets is the hallmark of Audi's sporty top models and a familiar

feature of the current RS generation.

Typical of the side view of the R8 is the sideblade. Much wider in

the bottom third, it visually accentuates the engine's position as

well as acting as an enlarged air deflector.

The continuous aluminum spoiler lip that connects the front and rear

diffusers with side air baffles below the enlarged sills also pays

tribute to this version's highly developed dynamic talents.

And yet the R8 is unmistakable for its powerful, elegant basic

proportions. The selective but always precise use of lines is

another typical Audi characteristic, as is the curved arc of the

roof. One new aspect is the glass roof of the passenger compartment

with two large transparent sections. These, together with the glazed

engine compartment behind, create a radically new formal element.

The unmistakable NACA duct in the middle of the roof is a functional

detail that is normally reserved for racing cars. Its ingenious

shape accelerates the air drawn in here for the two cylinder banks

of the V12 TDI engine.

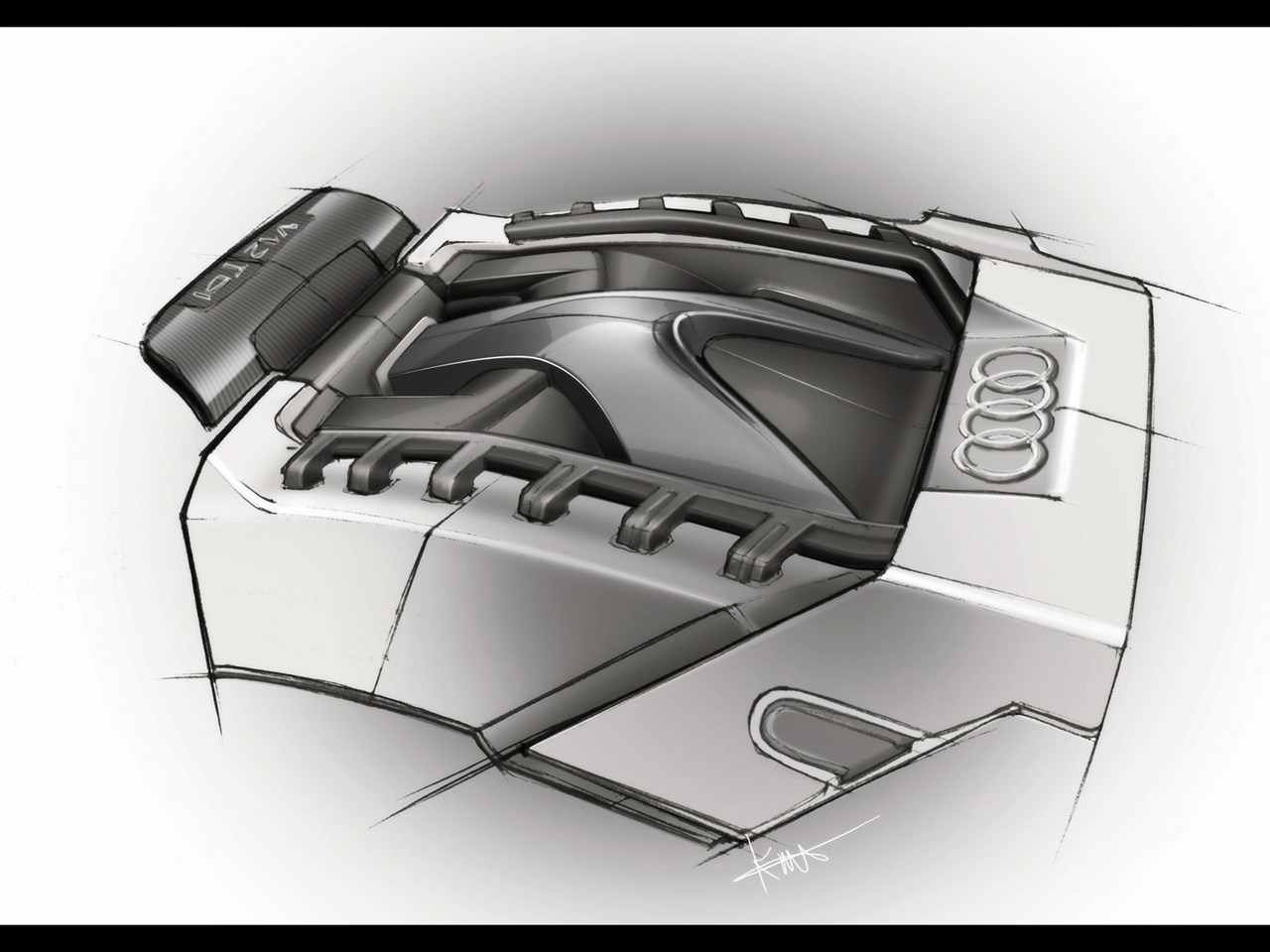

The V12 TDI is displayed as the beating heart of this sports car,

like a work of art inside a large showcase. Its look, underscored by

the air deflectors located beneath the restyled rear glass lid,

differs clearly from its production counterpart. The engine can even

be seen after dark, when white light-emitting diodes illuminate the

engine compartment as on the production R8 version. This

"showroom" can additionally be fully lined in genuine carbon fiber,

for a particularly exclusive look.

The continuous line running from the front apron across the wheel

arches and flanks to the tail end, then back down the other side, is

one of the latest design hallmarks of the Audi brand. This "loop"

naturally encompasses the air apertures, the headlights and the

taillights.

Unmistakable Face by Day and Night

The passion expressed through the elaborate design of the lights is

another typical Audi trait. Nor is anyone likely to overlook this

Audi sports car from behind: the LED taillights have a

three-dimensional look that cant be missed.

But the absolute highlight is the all-LED headlights of the study

vehicle. With their lenses and reflectors, not only do these

innovative light sources have a ground-breaking appearance, they

also have an enormous functional advantage: LED light, with its

color temperature of 6,000 Kelvin, resembles daylight much more

closely than xenon or even halogen light. Better light means the

driver will have much less fatigue when driving at night.

Ergonomic and Elegant

The interior's design is as sporty and exclusive as the exterior:

the characteristic element here is the monoposto an expansive arc

running around the steering wheel and instruments, connecting the

driver to the car. The interior consequently picks up on the

dynamism of the R8 TDI Le Mans and gives it tactile expression in a

form that is accessible the moment you climb in.

The three-spoke sport steering wheel of course remains the focal

point of the car's controls. With a diameter of 365 mm (14.37 in.),

it is both sportily compact and ergonomic in shape. The steering

wheel rim has a flat lower edge. This is a further aspect of the

auto racing feel in the Audi R8 TDI Le Mans, but one that also

brings major functional benefits, facilitating entry and exit for

the driver. The steering wheel is covered in fine Valcona leather,

with a diecast magnesium core providing strength.

The start/stop button for the engine and the Drive Select switch

with the Dynamic/ Sport/Race settings are arranged on the steering

wheel. The latter controls the engine and transmission electronics

as well as the magnetic ride dampeners in each of three different

modes.

In Race mode, the instrument lighting changes from white to red. The

navigation system shows a combined display with lap timer and

navigation information for the racetrack being driven. Or

supplementary information such as centrifugal force and boost

pressure can be called up.

Concentrating on the essentials was the priority in the ergonomic

arrangement of all Audi R8 versions. The most important

consideration particularly for high-speed driving is short reach

distances for all controls, to keep the time that the driver has

only one hand on the steering wheel to a bare minimum. In typical

Audi style the monitor is well within the field of view, and the

elements of the MMI operating system are located directly below it.

Compared with the production version, the R8 TDI Le Manss interior

has much larger aluminum applications, especially around the center

console. The many carbon fiber elements give the interior a

decidedly sporty feel.

The R8's exceptional everyday practicality for a sports car is

maintained in the study vehicle's spaciousness, even though the

longer engine takes up more room. The two occupants have the

generous wheelbase of 2.65 meters (8.69 ft.) to thank for the

interior comfort. This means the driver and passenger will always be

able to find their perfect seated position, whatever their build.

The view is also very good for a mid-engine vehicle. Narrow A-posts

optimize the field of view to the front and sides.

Light but Highly Rigid Body

The body of a sports car needs to be particularly light and rigid.

Low weight permits superior road performance, and rigidity is the

crucial starting point for an agile driving feel allied to high

precision. The Audi Space Frame body, made from aluminum, provides

the ideal basis for this.

Audi has more expertise than any other manufacturer worldwide in the

design and production of vehicles based on aluminum technology, and

has channeled its accumulated know-how into this area.

The entire bodyshell of the study car weighs just 210 kilograms

(462.97 lbs.). In ASF technology, the body's supporting structure is

made of extruded aluminum sections and die-castings. Aluminum panels

are incorporated into this skeleton to form a positive connection

and perform a load-bearing role. Each individual component of the

ASF space frame is optimized for its specific task by the use of

widely differing shapes and cross-sections, combining maximum

stability with minimal weight. It adds up to a car thats

particularly light and rigid, an outcome that can be felt in the

R8s ultra-precise driving feel.

The aerodynamics experts at Audi have done their work so thoroughly

on the study car that, as an added benefit of its elegant shape, the

body actually generates downforce unlike many other sports cars.

This aids directional stability at high speeds. It is achieved

partly by means of an extending rear spoiler that is much larger

than on the production version, and also thanks to the fully clad

diffuser underbody.

Two large-format diffuser apertures in the rear bumper demonstrate

just how much aerodynamics dictate the shape of the study vehicle.

The tailpipes of the exhaust system are located in pairs on the

right and left above the diffuser apertures. The add-on,

automatically extended rear spoiler also interacts with the air as

it flows around the car. The extra downforce it provides increases

the efficiency of the air intake generated by the aerodynamic design

of the underbody and diffusers. At low speeds, the rear spoiler

returns to its initial position.

Chassis

The precision chassis of the Audi R8 TDI Le Mans remains supremely

in control of the sporty performance, but is capable of assuring

relaxed driving pleasure over long distances too. The sports car is

spontaneous and agile at obeying steering movements, always

demonstrating exceptionally good driving safety. The suspension,

with double wishbones at both the front and rear, is optimized for a

neutral self-steering response and maximum ease of control.

The study car, too, has the innovative dampening technology known as

Audi magnetic ride. This adapts the chassis characteristic to the

profile of the road and the driver's style within milliseconds.

Ceramic Brakes with Extreme Reserves

A generously dimensioned brake system supplies the necessary braking

force. It applies a total of 24 pistons to the four brake disks,

combining excellent performance with minimal weight and high

durability. The disks are made from carbon fiber reinforced ceramic,

a material that has repeatedly proven its worth in the aviation and

aerospace sectors. The basis is very hard, frictionally resistant

silicon carbide, with its diamond-like crystalline structure.

Embedded in it are high-strength carbon fibers that absorb the

stresses occurring in the material. The intricate geometry of

cooling ducts in the ventilated disks prevents extremely high

temperatures. The ceramic brake disk ring is bolted by 10

spring-loaded elements to a stainless steel central element that

acts as the connection with the wheel's hub.

The ceramic brakes are identifiable at a glance by the special red,

six-piston monobloc aluminum calipers and the fixed calipers at the

rear. The advantages of the ceramic brakes include a further

reduction in weight of around 20 kilograms (44.09 lbs.), which in

this case improves the handling characteristics and comfort. The

high abrasion resistance permits an operating life of up to 300,000

kilometers (186,411 miles). Their key strength, however, is their

ability to withstand very high loads. Even on the racetrack, for

example, the ceramic brakes always maintain their full reserve

performance.

Vorsprung durch Technik: Diesel Milestones from Audi

Audi has reached another milestone in diesel technology with the new

V12 TDI. The brand with the four rings has been performing vital

pioneering work in this area for the past three decades. The first

TDI auto engine made its debut in 1989. The 2.5 liter five-cylinder

power unit developed 88 kW (120 hp) and 261 Nm, catapulting diesel

driving into an entirely new dimension.

This was followed in 1994 by a development version generating 103 kW

(140 hp). This engine was optionally available with all-wheel drive

the first TDI quattro model. A new four-cylinder diesel appeared

at that time in the Audi 100 and Audi 80, the 1.9 TDI developing 66

kW (90 hp) that has now become legendary.

At the end of 1995 the output of this four-cylinder unit rose to 85

kW (115 hp) with the advent of pump-injector fuel injection.

Slightly more than one year later, at the start of 1997, the world's

first 2.5 V6 TDI appeared.

With four valves per cylinder, it achieved an output of 110 kW (150

hp), and its top speed of 220 km/h (136.70 mph) made the Audi A8 the

fastest production diesel on the market. The first eight-cylinder

TDI followed in 1999 a V8 engine with a 3.3 liter capacity. The

3.0 TDI made its debut early in 2004 as the first V6 diesel with

inline piezo injectors in the common rail system.

The 4.2 liter TDI launched in the A8 in 2005 is currently at the

vanguard of Audi's TDI range. One in three A8 buyers in Germany

chose this V8 engine. The next logical step was to make the V8 TDI

available in the Audi Q7 in summer 2007.

With extremely clean, ultra-low emission technology, Audi is

continuing its tradition of leadership in diesel engine technology.

In 1989 it was the Ingolstadt brand that developed direct injection

technology. Since then the diesel engine has become around 30

percent more efficient.

The Euro 4 European emission standard has reduced particulate

emissions for cars by 93 percent. Long before it came into force,

Audi had models on the market that met this standard, even without a

particulate filter. And the brand will be offering the world's

cleanest diesel engines in production vehicles in 2008. The TDI

engines with the ultra-low emission system will be the first in the

world to meet the forthcoming EU 6 emission standard as well as the

toughest known statutory limits that apply in the U.S.

The equipment and specifications stated herein refer to the model

line offered for sale in Germany. Errors and omissions excepted.