2010 Jaguar C-X75 Concept

|

Price |

-- |

Production |

-- | ||

|

Engine |

gas turbine electric |

Weight |

-- | ||

|

Aspiration |

-- |

Torque |

1180 lb-ft | ||

|

HP |

778 hp |

HP/Weight |

-- | ||

|

HP/Liter |

-- |

Range |

560 miles | ||

|

0-62 mph |

3.4 seconds |

Top Speed |

205 mph |

(from Jaguar Press Release) Jaguar C-X75 Overview

“Performance through innovation has always been a Jaguar hallmark. From the beginning, cars such as the C-Type and D-Type pioneered aluminum construction, aerodynamic design, racing monocoques and disc brakes. The C-X75 demonstrates that the company is still leading the field in automotive design and technology.”

Dr Ralf Speth, Chief

Executive Officer, Jaguar Land Rover

The C-X75 concept is both a celebration of 75 years of iconic Jaguar

design and a look into the future of automotive technology. Designed

as a range-extended electric two-seater supercar, it explores the

outer limits of both performance and sustainability. With plug-in

capability the car can achieve a zero tailpipe emissions range of

110km (68 miles) – three times round Paris’s Péripherique – when

running under battery power alone, plus a potential top speed of

330kph (205mph) and blistering acceleration. The car demonstrates

that it is possible to retain Jaguar’s core values of performance,

design and luxury using technology that will make environmentally

responsible performance and electric vehicles a practical

proposition.

The aim was to produce not only the most innovative but also one of

the most beautiful Jaguars ever; one which hints at an exciting

evolution of the marque’s award-winning design language while paying

homage to some of its most admired cars of years gone by. Advanced

design features such as a ground-breaking propulsion system and

active aerodynamics allow for an elegantly simple fuselage section

that remains stable at very high speeds.

“The C-X75 is a tribute to the people who shaped the iconic Jaguars

that are revered to this day. By making it an innovative test-bed

for the technologies of tomorrow, it also ensures that our

reputation for engineering excellence will continue for another 75

years and beyond.”

Mike O’Driscoll, Managing Director, Jaguar Cars

The C-X75’s 580kW (778bhp) propulsion system combines powerful 145kW

(195bhp) electric motors at each wheel for outstanding performance.

At the center of the car sit state-of-the-art, mid-mounted micro

gas-turbines. These can either generate 140kW (188bhp) to charge the

batteries and extend the range of the car to a remarkable 900km (560

miles) – enough to drive from London to Berlin on a single tank – or

when in Track mode provide supplementary power directly to the

electric motors. The four electric motors provide torque-vectored,

all-wheel drive traction and grip, essential in a car that produces

580kW (778bhp) and 1600Nm (1180lb ft) of torque.

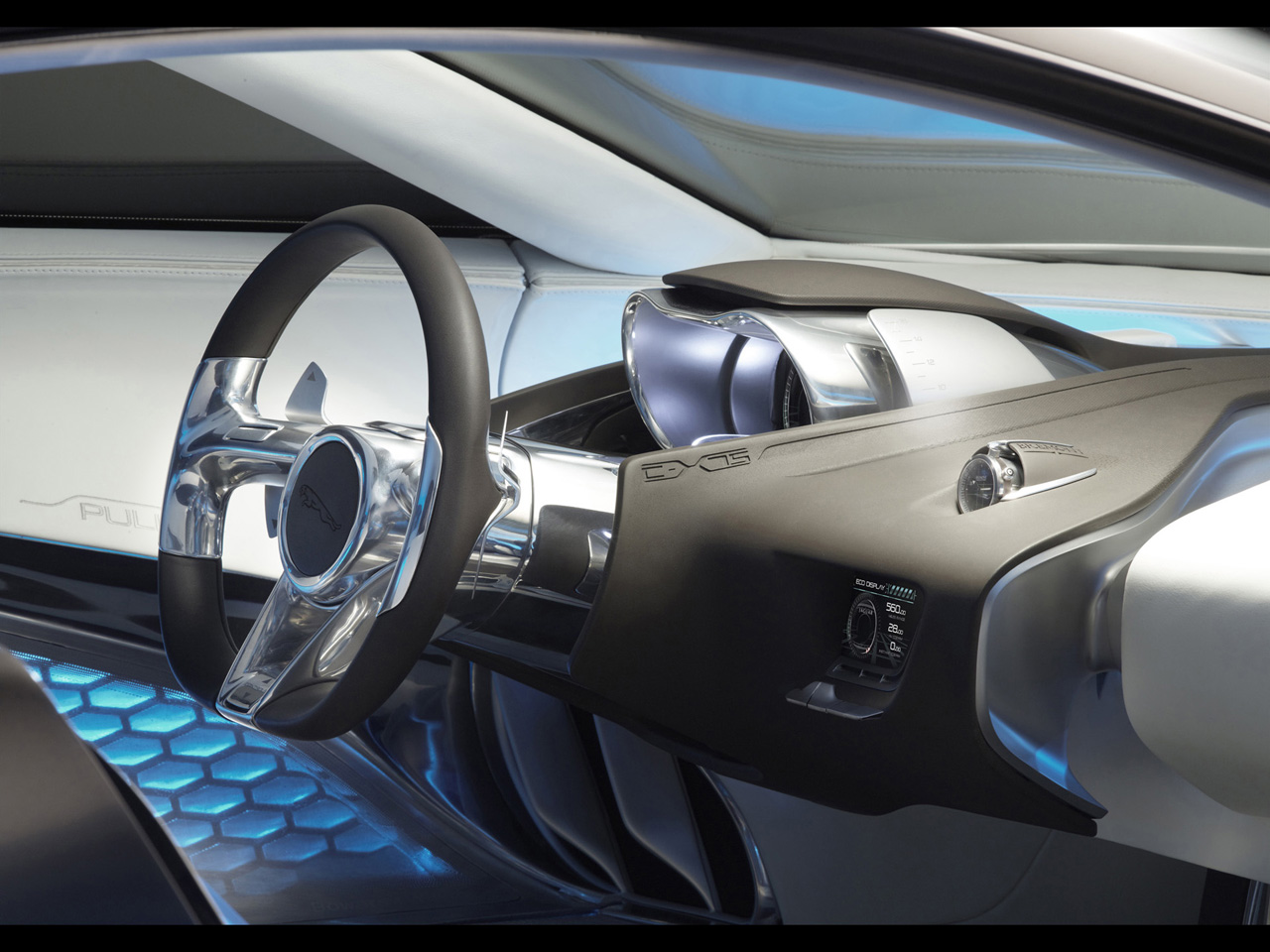

The car’s interior is equally impressive, with the driver and

passenger seated ahead of a sealed airbox that houses the micro

gas-turbines. The seats are fixed to the bulkhead as in a single-seater

racing car, and air to feed the turbines passes smoothly around them

via channels in the structure of the body. With the seats anchored

in place, the steering wheel, controls, main binnacle and pedal box

all adjust towards the driver.

Dramatic theater lighting is activated as the driver approaches the

car; phosphor blue electro-luminescent wire lights illuminate the

perimeter of the cabin and the turbines. When the car is started,

additional blue LED lighting gently floods the door and bulkhead

speaker cavities, highlighting the car’s lightweight construction.

Bespoke interior materials include cream and grey leathers, polished

and vapor-blasted aluminum and a soft-feel textured neoprene.

A new interface for the driver has also been created for the C-X75

using high-resolution TFT screens. Building on Jaguar’s 10-year

expertise in touchscreen technology, the Jaguar Co-Pilot display in

the center console supports the driver in extracting the full

potential of the C-X75 by seamlessly managing information.

The C-X75 – At a Glance

DESIGN – A celebration

of 75 years of beautiful, fast Jaguars which points the way to a new

design language

PERFORMANCE – 0-100kph (62mph) in 3.4 seconds, top speed of 330kph

(205mph) and 80-145kph (50-90mph) in just 2.3 seconds

PROPULSION SYSTEM – A Range-Extended Electric Vehicle (RE-EV) using

a unique combination of electric motors and micro gas-turbines to

increase its range to 900km (560 miles)

EMISSIONS – A zero tailpipe emissions range of 110km (68 miles)

while running solely on battery power

SUSTAINABILITY – By capitalizing on its plug-in charge capability

the C-X75 will produce just 28 grams of CO2 per kilometer on the EU

test cycle

CONSTRUCTION – Jaguar’s advanced lightweight aluminum construction

techniques provide great weight-saving and economy benefits.

Additionally, up to 50 percent of the metal content is recycled

ACTIVE AERODYNAMICS – Drag coefficient of 0.32Cd and active

downforce created through the use of an underbody Venturi

THEATER – A dramatic entrance to the car is created by striking

electro-luminescent wire lighting which alters to enhance the

driving experience

UNIQUE USER INTERFACE – The touchscreen Jaguar Co-Pilot interface

manages the information workload by predicting the needs of the

driver

BESPOKE MATERIALS – Interior seamlessly blends traditional,

hand-tailored leathers with textured neoprene panels and two

different aluminum finishes

Jaguar C-X75 Design - At a Glance

CELEBRATING 75 YEARS –

Entirely forward looking, the C-X75 marks three-quarters of a

century of iconic Jaguar design

FUTURE FOCUS – The current XF, XK and XJ have already won plaudits

for their design and the C-X75 points the way to an evolving future

style language

DESIGN-LED SOLUTIONS – An elegant demonstration of how Jaguar’s core

values – performance, design, luxury – will be delivered in the

future

DESIGN PURITY – The simple tubular fuselage exterior shape of the

C-X75 has been achieved without sacrificing aerodynamic efficiency

AIRFLOWED INTERIOR – The simple, flowing curves of the interior are

inspired by the movement of air to the turbines

DRIVER-FOCUS – The C-X75 tailors itself perfectly to the driver

through an adjustable instrument binnacle, steering wheel and pedal

box

INTERIOR THEATER – Unique interior electro-luminescent wire lighting

welcomes the driver to the car and alters its output according to

driving mode

CABIN TECHNOLOGY – An innovative nano-technology sound system offers

active noise-cancelling and an exclusive clock is wound by the

acceleration and braking forces of the car

UNIQUE MATERIALS – Bespoke interior materials combining

Jaguar-commissioned leathers, metal micromesh panels, soft-feel

textured neoprene and a mixture of polished and vapor-blasted

aluminum surfaces

75 Years of Jaguar Design

For 75 years, Jaguar has

been responsible for some of the most iconic road and racing car

designs ever seen. The roll call of names will be familiar to all:

XK120, C-Type, D-Type, XJ13, E-Type, XJ220. To that list can now be

added the C-X75, which celebrates three-quarters of a century of

beautiful, fast Jaguars by being the fastest and perhaps most

beautiful concept of them all.

Jaguar has an award-winning portfolio of designs in its current

range of XK, XF and XJ models and the C-X75 reinforces the marque’s

design-led approach to product development. Created under the

guidance of Design Director Ian Callum, the concept points the way

towards an even more emotive design language which combines

beautiful contemporary styling with world-class research and

engineering.

Aficionados will identify elements from Jaguars of the past in the

C-X75 but the intention was not to look back but forward. The

C-X75’s designers stayed true to the long-held Jaguar design

philosophy of natural, flowing lines and simple, elegant forms.

Where inspiration from the past was found was in the innovative

engineering and functional design elements of cars like the 1950s

C-Type and D-Type racers and unique 1966 XJ13 Le Mans prototype – a

car described by Callum as, “possibly the most beautiful Jaguar ever

made.”

Just as the XJ13 acted a test-bed for a new engine, the C-X75 offers

similarly positive and inspiring potential solutions to the

challenges posed by environmental concerns. Performance cars have

always aimed for efficiencies in terms of weight, agility and

dynamics, all of which also benefit economy. Using previously unseen

combinations of technology, the C-X75 supercar provides a glimpse

into the future of Jaguar and its commitment to producing beautiful,

fast cars powered by sustainable means.

Exterior Design

“The C-X75 is everything

a Jaguar should be. It possesses remarkable poise and grace yet at

the same time has the excitement and potency of a true supercar. You

could argue this is as close to a pure art form as a concept car can

get and we believe it is a worthy homage to 75 years of iconic

Jaguar design.”

Ian Callum, Design Director, Jaguar Cars

Finished in Jetstream Silver, the C-X75’s beautiful proportions,

sculpted lines and powerful stance have been created, in the words

of Julian Thomson, Assistant Design Director and head of the Jaguar

Advanced Design Studio, to ”pull at the same emotional heartstrings

as classic Jaguars such as the D-Type and XJ13 racers.”

The C-X75 borrows more than simply elegant looks from previous

classic designs, however, for those cars were equally respected for

the purity of their engineering. C-X75 has been created to indicate

the future for luxury carmakers such as Jaguar. It shows that it is

possible to retain core brand values while offering zero emissions

motoring for much of the time, as well as range-extending

technologies that will make electric vehicles significantly more

practical.

Aerodynamic Purity

Shorter, slimmer and

lower than the current crop of supercars, its exterior design is

about pure performance with a simple central fuselage surrounded by

prominent wheelarches. Thanks to the packaging efficiencies provided

by the absence of a conventional piston engine, the car’s designers

had maximum freedom in placing the mechanical components and

creating the most elegant engineering package available.

Consequently the car has the most perfect proportions and sense of

balance possible with a compact cabin placed centrally between the

dramatic wheel arches. The lines of the supercar are purposeful and

agile, suggesting a sense of movement and poise.

Aerodynamics are a key factor in designing a supercar capable of

accelerating to speeds in excess of 320kph (200mph). Yet, as Thomson

explains, the designers weren’t prepared to sacrifice the car’s

beauty when it came to creating downforce and stability at high

speeds:

“Because we want this to be one of the most beautiful Jaguars ever,

we took a much more elegant approach to the C-X75’s aerodynamics and

exploited the benefits of having an electrically-powered drivetrain.”

Using an underbody Venturi and directional exhaust gas control kept

the car as sleek, compact and low as possible while still generating

immense amounts of grip and downforce. Indeed, the movement of air

itself was one of the principle drivers behind many of the design

cues that were incorporated into the bodywork. Principal designer

Matt Beavan reveals how the airflow into the turbines helped to

shape the surfaces of the car itself:

“We wanted to emphasize how the air makes its way not just over the

car but is also channeled into the rear airbox. When operating at

80,000rpm, each gas-turbine requires 25,000 liters of air a minute

which means we need a series of carefully honed intakes.”

The two beautifully sculpted sill-mounted aluminum intakes have a

striking two-tone finish, with polished inner surfaces emphasizing

their functionality. Above them sit two further intakes that feed

cold air to a separate turbine cooling system.

The turbine theme is also echoed in the stunning alloy wheels which

appear to have been cut from a single block of aluminum with a spoke

design inspired by the fan blades of the engines themselves. The

tires have been custom-made by Pirelli with an asymmetric tread

pattern and bold green F1-style wear indicator running the

circumference of the tire.

Forward-hinged doors are opened using Jaguar Sense touch technology,

raising outwards and upwards for excellent cabin access. To maintain

the purity of the side profile, the designers replaced conventional

door mirrors with cameras housed in a tailfin which is a

miniaturized echo of that of the D-Type – images are displayed on

screens inside the cabin. Behind the doors, fuel fillers sit either

side of the cockpit – reminiscent of the twin-tank system on the

original XJ6 – which on the C-X75 access respectively the fuel tank

for the turbines and the plug-in battery charging point.

The eye is then drawn towards the sealed compartment which houses

the twin micro gas-turbines and the beautiful structural bracing

that supports them. Exposed through the rear window – much like with

the XJ13 – the remarkable turbines are showcased by their elegant

aluminum housing and Texalium woven fabric lining the engine bay.

The compact packaging of the turbines allowed the designers further

freedom at the rear of the car, which is shaped like the trailing

edge of an aircraft wing. This is both functional – incorporating

the Venturi aerofoil – and beautiful with a sharp swage line and

dramatic, slim full-LED rear lights.

Interior

Jaguar has a long

tradition of using the finest materials to create a cosseting and

luxurious cabin that allows the driver to concentrate on the

experience of driving, culminating in the award-winning interior of

the current XJ. With the C-X75, Jaguar has blended beautiful

leathers with innovative materials and finishes to create an

elegantly tailored and driver-focused cabin that is defined and

inspired by the technology that powers this sustainable supercar.

The twin micro-turbines provided great inspiration when designing

the interior architecture. The turbines themselves require vast

amounts of air and driver and passenger are placed in the calm

centre of this storm. The soft shapes and surface changes of the

cabin reflect the movement of air, unseen and unheard by those

inside, within the channels surrounding it.

The seats are fixed into the rear bulkhead that forms part of the

airbox feeding the turbines, integrating driver and passenger not

only into the structure but also the function of the car. A

beautifully formed aluminum spar directs air into the turbines which

are supported by spiral-shaped cast brackets that appear to flow

directly from the seats’ headrests.

Driver-focused cabin

While Jaguar cabins have

always been calm, comfortable sanctuaries for passengers, their

focus has remained centered on the driver. The C-X75 takes this

commitment to its logical conclusion by placing the driver as close

as possible to the centre of the car. As a result the cabin tailors

itself perfectly and uncompromisingly to the driver. A rocker switch

on the steering wheel brings the wheel and instrument panel towards

the driver, revealing a beautifully polished aluminum surround to

the binnacle. The pedal box is likewise fully adjustable to create

the perfect driving position.

The sense of occasion and driver experience engendered by the C-X75

is unsurpassed. Electro-luminescent micro-wires and LEDs use vibrant

light to create two very different environments within the cockpit,

making it feel incredibly dramatic and highlighting the car’s width.

As the driver approaches the car, a bright ring of phosphor blue

wire lighting outlines the extreme plan shape of the car by leading

the eye around the monocoque tub and into the turbine chamber.

When the driver enters, the electro-luminescent wire illumination is

replaced by LEDs emitting a phosphor blue light that dims as the

occupants settle themselves into the cockpit. This gentle

illumination from inside the doors and bulkhead cavities creates a

translucency inspired by lightweight aircraft structures and exposes

the Bowers & Wilkins nano-speaker panels behind the micromesh.

Additional LEDs behind the dashboard and underneath the turbines

make both installations appear to ‘float’ inside the structure of

the car.

The car is started using a switch mounted in the aircraft-inspired

overhead control panel. Twin needles indicating turbine

functionality sweep dramatically around the edge of the main dials

and back to rest.

When driven in Track mode the cabin changes character once again –

taking inspiration from fighter aircraft in combat mode. The Jaguar

Co-Pilot touchscreen system switches to stealth and all ambient

cabin lighting fades to minimize driver distraction. The

electro-luminescent wire now forms blades of blue light which

outline the driver’s seat and controls.

The lighting however is not the only feature which lends a sense of

theatre and uniqueness to the experience of piloting the C-X75. The

gear-selector is modeled on a fighter jet’s throttle control and

includes a manual override for the turbines, allowing them to run

continuously for maximum charge.

Unique Materials

A unique, sustainable

performance supercar, the C-X75 utilizes materials that reflect its

design and engineering ideals. A luxurious cream Ceramic

semi-aniline leather was chosen for the dashboard to complement the

purity of the polished aluminum. In contrast, a more technical

full-aniline Storm Grey leather was used on the seats. The leathers

themselves have their own sustainability story, having been sourced

from Scottish company Bridge of Weir, one of the most modern and

environmentally efficient leather producers in the world.

To highlight the main driver interfaces, the instrument binnacle,

gear selector and certain areas of the steering wheel are covered in

a soft-feel textured neoprene. This malleable material allowed the

designers to sculpt soft, flowing surfaces that encase the technical

hardware. The leading edges of the instrument binnacle have a satin

smooth finish while further back the material is covered in grains

subtly shaped like the traditional Jaguar ‘lozenge’ logo.

Reflecting the polished working surfaces on the exterior of the car,

the air-conditioning vents also feature a dual finish although this

time it is reversed, with mirror-finished external surfaces and

vapor-blasted matt interior. Inside the vents can be found an

aluminum honeycomb structure similar to that used in aircraft

construction.

Jaguar C-X75 Innovation - At a Glance

PERFORMANCE – 0-100kph

(62mph) in 3.4 seconds, a top speed of 330kph (205mph) and 80-145kph

(50-90mph) in just 2.3 seconds

EFFICIENCY – Explores the outer limits of Range-Extended Electric

Vehicle (RE-EV) technology with CO2 emissions of just 28g/km and a

range of 900km (560 miles)

ZERO EMISSIONS – Fully charging the C-X75 from a domestic power

supply takes six hours and allows the car to run with zero tailpipe

emissions in electric-only mode for 110km (68 miles)

PROPULSION SYSTEM – 2 x 70kW (94bhp) micro gas-turbines and the

plug-in Lithium-ion batteries provide power to four independent

electric motors each rated at 145kW (195bhp) and 400Nm (295lb ft) of

torque. These in turn provide drive to all four wheels

CONSTRUCTION – Uses Jaguar’s advanced lightweight aluminum

construction techniques. Additionally, up to 50 percent of the metal

content is recycled

ACTIVE AERODYNAMICS – An underbody Venturi system incorporates a

movable aerofoil and directional control of the exhaust gases to

provide maximum downforce without using spoilers

DRIVING POSITION – An electrically adjustable instrument binnacle,

steering wheel and pedal box ensures the car is perfectly tailored

to the driver

HUMAN MACHINE INTERFACE – Data from the car’s complex systems are

shown on three information screens and can be transferred and

filtered between displays as needed

Jaguar C-X75 - Innovation

“This evocative showcase

of 75 years of performance heritage, the C-X75 also demonstrates

Jaguar’s commitment to developing cutting-edge engineering solutions

to the challenges facing future automotive development. The supercar

shows that Jaguar will continue to build beautiful, fast cars that

will generate their performance in a sustainable manner.”

Ian Hoban, Vehicle Line Director, Jaguar Cars

The Jaguar C-X75 is a high-performance demonstration for future

technology and innovation. The 330kph (205mph) four-wheel drive

supercar is capable of reaching 100kph (62mph) from rest in 3.4

seconds with zero tailpipe emissions during urban use. Even in

range-extending mode it emits just 28 grams of CO2 per kilometer

thanks to its ultra-efficient micro gas-turbines which provide

charge to four 145kW (195bhp) electric motors.

A six-hour plug-in charge of the Lithium-ion batteries allows an

electric-only range of 110km (68 miles). However, as a

Range-Extended Electric Vehicle (RE-EV), the C-X75 removes the range

anxiety that currently hinders the mainstream adoption of electric

vehicles. The innovative twin turbines can either charge the car’s

batteries on-the-fly, allowing the supercar to travel 900km (560

miles) between fill-ups or, in Track mode, automatically provide

supplementary power directly to the electric motors to allow the car

to top 330kph (205mph).

In creating the C-X75, Jaguar, under the aegis of the Government

sponsored Technology Strategy Board (TSB), has worked closely with

other British firms, each of which is at the forefront of its field.

The TSB is a public body that brings together businesses in a range

of programs to drive innovation with an emphasis on sustainability.

Jaguar’s partners in this project are Bladon Jets, makers of the

micro gas-turbines, and SR Drives who supply the switched reluctance

generators.

The decision to use technology originally designed for aeronautical

applications was an obvious one given both Britain’s and Jaguar’s

heritage in this area. Born in Coventry, a short distance from the

site of what would become the Jaguar’s historic Browns Lane factory,

Sir Frank Whittle is credited with developing the gas-turbine jet

engine. It is Whittle’s concept that has been refined by supplier

Bladon Jets into the compact, efficient powerplant used by Jaguar in

the C-X75.

Jaguar itself has an aeronautical heritage, a number of great

Jaguars of the past – C-Type, D-Type and E-Type – were shaped by

aerodynamicist Malcolm Sayer. Aircraft-inspired technology also led

to the development of the aluminum spaceframe chassis around which

those early Le Mans-winning Jaguars were constructed; the same

technique used today in the C-X75.

For the C-X75 Bowers & Wilkins, the supplier of exclusive premium

audio systems for Jaguar, has explored future audio technologies to

develop a product that delivers unrivalled sound quality while

making extremely low power demands.

Advanced aluminum lightweight construction

Jaguar’s expertise in

the use of aluminum stretches back more than 50 years to the first

XK120s, through the lightweight E-Types and pioneering X350 to the

XK and all-new 2010 XJ. It was with this latter creation that Jaguar

fully realized the lightweight metal’s benefits to performance,

agility, economy and sustainability in a luxury car, creating a lead

its rivals have yet to close.

The C-X75 naturally follows the same construction techniques with an

extruded and bonded aerospace-inspired aluminum chassis clad in

panels of the same material, making it significantly lighter than

current supercars. Not only does this save weight, crucial in a car

with an extreme performance envelope, but aluminum is one of the

most easily recyclable metals available, boosting the C-X75’s

sustainability as well as its speed. As with the current XJ, up to

50 percent of the supercar’s structure is made from recycled

aluminum.

Active Aerodynamics

Aerodynamics have always

played a large part in Jaguar design with legendary designer Malcolm

Sayer elevating it into an art form in cars such as the XJ13, the

prototype from which the C-X75 draws inspiration.

Today Jaguar is aiming to reduce the drag coefficient of its future

models in order to increase fuel efficiency. The C-X75 presented the

additional challenge of managing the high volume of air required by

the turbines. To achieve this active aerodynamics have been utilized

for the first time on a Jaguar.

By opening the front grille and brake cooling vents only when

necessary, Jaguar has increased the design’s aerodynamic efficiency

dramatically. At the rear corners of the car vertical control

surfaces automatically engage at higher speeds to direct airflow aft

of the rear wheels for increased stability and efficiency.

The carbon-fiber rear diffuser, a crucial element in guiding airflow

under the car and creating downforce includes an active aerofoil,

which is lowered automatically as speed increases. Vanes in the

exhaust ports then alter the directional flow of the gases to

further increase the effectiveness of the Venturi tunnel.

Propulsion System

Jaguar has already made

a sizeable commitment to developing future generations of cars that

minimize their impact on the environment. Jaguar is aiming to reduce

its carbon dioxide emissions by a quarter over the next five years

and as a business £800m is being invested in research into

innovative solutions to forthcoming sustainability challenges.

The C-X75 is capable of running in purely electric, zero tailpipe

emissions mode for 110km (68 miles) on a six-hour domestic plug-in

charge. However, unlike a conventional electric vehicle, the

enjoyment of this supercar won’t end there. The innovative,

lightweight micro gas-turbines are capable of very quickly and

efficiently recharging the Lithium-ion batteries, giving the car a

theoretical range of 900km (560 miles) and can also automatically

provide supplementary power directly to the motors when in Track

mode.

This remarkable range-extension system is a result of Jaguar’s

research engineers adopting a clean-sheet approach to the question

of powering the supercars of the future. The C-X75 turns to the very

latest evolution of a pioneering piece of British technology: the

gas turbine.

British engineering firm Bladon Jets achieved a recent breakthrough

in producing the multi-stage axial flow compressors – the technology

used on all large gas turbines – on a miniaturized scale and to very

high tolerances. This increased the compression and efficiency of

micro gas-turbines to the point at which they can be viewed as a

realistic power source. Each of the micro gas-turbines weighs just

35kg and produces 70kW of power at a constant 80,000rpm.

Because the exhaust gases form part of the active aerodynamic

package, Jaguar has utilized a specialized zirconia-molybdenum

coating. This advanced heat-resistant coating is regularly used in

Formula One cars and is applied in a plasma spray to the

carbon-fiber diffuser to protect it from the exhaust gases.

Turbines offer a number of advantages over a reciprocating piston

engine when powering range-extending generators. With fewer moving

parts and air bearings, turbines do not need oil lubrication or

water-cooling systems, all of which offers considerable

weight-saving benefits. They can also be run on a range of fuels

including diesel, biofuels, compressed natural gas and liquid

petroleum gas.

Turbines reach their optimum operating speed and temperature in

seconds and so can be used in short bursts to top up the batteries

without compromising fuel consumption or life-cycle. Coupled to two

switched reluctance generators supplied by SR Drives, the turbines

operate either in sequence or together, depending on energy needs,

to swiftly and efficiently charge the batteries – or provide power

directly to the electric motors – as dictated by the propulsion

system supervisory system.

Battery technology is currently the greatest limiting factor in the

development of high-performance electric vehicles with a realistic

range. Jaguar’s engineers are currently carrying out research with

leading battery suppliers into the next generation of power cells in

order to find the best compromise between energy and power

densities. The batteries used in the C-X75 are of a state-of-the-art

composition which offers significant benefits in terms of weight,

lifecycle, energy density and safety.

Power and Control

The energy created by

the turbines and stored in the batteries is transmitted to the road

using four independent electric motors. Using individual motors has

benefits in terms of weight saving and distribution, packaging and

efficiency. Each motor weighs just 50kg but produces 145kW (195bhp)

of power and an astonishing combined total torque output of 1600Nm

(1180lb ft).

Because each wheel is driven by its own electric motor, the C-X75 is

four-wheel drive – with all the traction, grip and safety benefits

that entails – without the weight disadvantages of a purely

mechanical set-up. Inherent in this drivetrain is the ability to

independently vector torque to each wheel across the full speed

range. This offers potential benefits in terms of stability and

control, creating an infinitely and instantaneously adjustable

traction and stability control system.

Electric motors also produce maximum torque from almost zero rpm,

making the traditional power curve a thing of the past. In fact,

such is the C-X75’s power that Jaguar’s engineers had to

artificially limit the torque available from rest in order to

improve the driveability of the car. The performance available in

the mid-range is truly startling. The C-X75 will accelerate from

80-145kph (50-90mph) in just 2.3 seconds. The quarter-mile sprint

takes 10.3 seconds at a terminal velocity of 251kph (156mph) and

acceleration peaks at 0.88G.

Such astounding performance requires equally impressive braking.

Jaguar already has a system proven to be up to the task. The C-X75

is fitted with the brakes used on the supercharged XFR which in 2009

became the fastest Jaguar ever, achieving 363kph (226mph) at the

Bonneville Salt Flats in Utah. In this application, regenerative

braking technology on all four wheels helps recharge the batteries

during driving. The 380mm internally ventilated front discs and

345mm rears are covered by polished alloy wheels of 21 and 22 inches

respectively.

Interior Innovation

The driver-focused interior of the C-X75 is a statement of intent from Jaguar, using cutting-edge technology that is seamlessly integrated into the car in order to enhance the driving experience. In creating the C-X75, Jaguar has forged relationships with other British companies that share its philosophy of engineering and design purity.

Fingertip Information Control

As on the new XJ,

traditional analogue instruments have been replaced with

high-resolution TFT-LCD technology for all three Human-Machine

Interfaces (HMI) within the cockpit.

The main Driver Information screen is housed within the instrument

binnacle. Needles float on the periphery of the twin cowls and sweep

round the outer edge to display the status and rpm of the two

turbines. The amount of information that can be displayed required a

new graphic interface. The design team combined designs from

instrumentation in the new XJ saloon with those from fighter

aircraft to create virtual 3D ‘gimbals’ around which the gauges wrap

and rotate to provide status updates.

Information on speed, acceleration, power production, power usage

and active aerodynamic status is selected using rocker action

paddles mounted on the steering wheel, giving the driver fingertip

control over all the complex systems of the car.

A secondary ‘Jaguar Co-Pilot’ touchscreen in the centre of the

dashboard is angled towards the driver and performs a predictive

function, suppressing superfluous information and allowing the

driver to concentrate on the task in hand. As its name suggests,

this seamlessly manages the relationship between car and driver. By

syncing with technology such as smart-phone calendars for instance,

it will recognize that the driver is due to attend a track session

at Le Mans and will not only offer to calculate a route but also

suggest activating high-performance modes once on the circuit

itself. Once accepted by the driver, this information wipes

seamlessly to the main binnacle display.

The two screens operate in three modes:

Standard Mode –

The left-hand dial displays speed, navigation information is shown

in the centre with range and time in the right-hand dial. The

Co-Pilot screen is used for economy and emissions data.

Track Mode – The right-hand dial changes to display available

power while the needles surrounding the binnacle show the turbine

status. The Co-Pilot screen changes to display performance and lap

time data.

Heritage – Both screens transform into accurate recreations

of classic D-Type instrumentation, demonstrating how owners might

download their own bespoke interfaces.

A third, smaller screen mounted low in the centre console displays gear information.

Bremont Watches

The need for the

information screens to be able to display information with timeless

clarity led to co-operation with Bremont, an independent British

company creating beautiful mechanical watches that are hand

assembled at their dedicated atelier in Switzerland. Its aviation

inspired designs and commitment to engineering excellence has seen

the company quickly establish itself in the world of authentic

luxury.

Jaguar designers took styling cues from the Bremont MB2 watch when

creating the graphics for the time related elements of the HMI. The

result is a perfect combination of traditional Jaguar warmth and

absolute purity and precision.

Bremont also produced a unique clock, which can be mounted in a

turbine-inspired holder in the centre console. The clock’s mechanism

uses the acceleration and braking forces of the car to keep it

wound.

The relationship with Bremont inspired another element of the

interior design. The company produces a watch, the MB1, exclusively

for those who have had their lives saved by the Martin-Baker ejector

seat. To date this British-developed safety system has saved more

than 7000 people. In recognition of this, the interior door release

handles of the C-X75 are crafted from aircraft-grade aluminum and

mounted in the base of the seat, in the same position as a fighter

jet ejector lever.

Surround Sound

Jaguar tasked its

existing in-car entertainment partner, audio experts Bowers &

Wilkins, with creating a revolutionary new sound system that reveals

how audio technologies are set to evolve.

The innovative result was a system that uses dozens of tiny moving

coil transducers arrayed in an ultra-thin honeycomb pattern that

allows them to line the doors and rear bulkhead. The housings,

magnets and coils are built up by the nanometer and faced in B&W’s

own polycrystalline diamond diaphragm material, the finest

available. The array of tiny speakers literally surrounds the driver

and passenger with a powerful and all-enveloping sound but their

small size also means the power draw of the system is kept very low.

This system also allowed the development of active sound cancelling

technology, isolating the cabin from the noise produced by the

turbines and creating a peaceful, luxurious cocoon allowing the

driver to focus on the enjoyment inherent in driving a Jaguar.

Similar technology could be used to cancel any noise broadcast to

the outside world by the turbine operation.